In today’s fast-paced world, the demand for smaller, more powerful electronic devices has never been greater. From smartphones and wearables to medical devices and aerospace systems, consumers and industries alike are demanding devices that are compact yet highly functional. This shift towards miniaturization is driven by the need for portability, efficiency, and innovation. High-Density Interconnect (HDI) PCBs have emerged as the secret weapon behind these compact electronics, enabling engineers to design devices that are smaller, faster, and more powerful than ever before.

Compact electronics are essential for a variety of reasons. First and foremost, consumers demand devices that are portable and easy to carry. Smartphones, for example, have evolved from bulky devices to sleek, pocket-sized gadgets that pack incredible performance. Second, advancements in technology have made it possible to integrate more functionality into smaller spaces. Medical devices, for instance, are now being designed to be smaller and more portable, enabling doctors and patients to use them in a wider range of settings.

In industries like aerospace and automotive, the need for compact electronics is equally critical. Space is often limited in these applications, and any reduction in size can lead to significant cost savings and improved performance. As a result, engineers are constantly seeking solutions that allow them to design smaller, more efficient devices.

High-Density Interconnect (HDI) PCBs are specifically designed to accommodate more components in a smaller space, making them ideal for applications that require high performance and a minimal footprint. By leveraging advanced features such as microvias, stacked vias, and blind vias, HDI PCBs allow engineers to design devices that are both smaller and more powerful.

HDI PCBs are particularly useful in applications that require high performance and a minimal footprint, such as smartphones, medical devices, and aerospace systems. By enabling compact designs and delivering superior performance, HDI PCBs have become a cornerstone of modern electronic design.

HDI PCBs are built using advanced materials and construction techniques that enable higher component density. Key features that enable miniaturization include:

These features allow engineers to pack more components into a smaller space, resulting in devices that are both smaller and more powerful.

HDI PCBs are used in a wide range of compact devices across various industries. For example:

Designing compact electronics is not without its challenges. Engineers must balance several factors, including size, performance, and cost. For example, while reducing the size of a device can lead to cost savings, it can also make the design more complex and increase the cost of materials.

Another challenge is ensuring that the device performs reliably, even in demanding environments. This requires careful consideration of factors such as heat dissipation, signal integrity, and component placement.

HDI PCBs address these challenges by offering a solution that enables higher component density and improved performance. The use of microvias, stacked vias, and blind vias allows engineers to pack more components into a smaller space, resulting in devices that are both smaller and more powerful.

Additionally, HDI PCBs offer improved thermal management, ensuring that the device remains stable and reliable even under heavy workloads. By managing heat more effectively, HDI PCBs ensure more stable and reliable operation, even in demanding environments.

Finally, HDI PCBs are increasingly being adopted in mid-range and even entry-level products, making them more accessible to a wider range of applications.

To better understand the impact of HDI PCBs on compact electronics, let’s take a look at some real-world success stories:

A leading smartphone manufacturer approached OneStopPCB with the challenge of designing a compact, high-performance PCB for their latest device. By leveraging our expertise in HDI PCB technology, we were able to deliver a PCB that met all of their requirements, including a compact design, high performance, and reliable operation.

The result was a smartphone that was thinner, lighter, and more powerful than ever before. Our customer was thrilled with the results, and we’re proud to have played a key role in their success.

A medical device company needed a high-performance PCB for their latest diagnostic equipment. The device required a compact design and reliable operation, even in demanding environments.

OneStopPCB worked closely with the company to design and manufacture an HDI PCB that met all of their requirements. The result was a medical device that performed reliably, even under heavy workloads. Our customer was impressed with the quality and performance of the PCB, and we’re proud to have helped them bring their product to market.

An aerospace company needed a compact PCB for their latest avionics system. The device required a compact design and reliable operation, even under extreme conditions.

OneStopPCB worked closely with the company to design and manufacture an HDI PCB that met all of their requirements. The result was an avionics system that performed reliably, even under extreme conditions. Our customer was impressed with the quality and performance of the PCB, and we’re proud to have helped them bring their product to market.

These case studies highlight the importance of HDI PCBs in enabling compact, high-performance designs. By leveraging advanced features such as microvias, stacked vias, and blind vias, engineers can design devices that are both smaller and more powerful.

Additionally, these case studies demonstrate the importance of partnering with a trusted PCB manufacturer. OneStopPCB’s expertise in HDI PCB technology, combined with our commitment to quality and customer satisfaction, makes us the ideal partner for your next project.

HDI PCBs are the key to compact electronics, offering a solution that enables engineers to design devices that are smaller, faster, and more powerful than ever before. By enabling compact designs and delivering superior performance, HDI PCBs have become a cornerstone of modern electronic design.

Whether you’re designing a smartphone, a medical device, or an aerospace system, HDI PCBs offer the performance benefits needed to succeed in today’s competitive market.

The role of HDI PCBs in innovation cannot be overstated. As technology continues to evolve, the demand for compact, high-performance devices will only increase. HDI PCBs are essential for meeting this demand, enabling engineers to design the next generation of innovative devices.

If you’re ready to take your designs to the next level, contact OneStopPCB today. With our expertise in HDI PCB manufacturing and our commitment to quality, we’re here to help you achieve your goals. Visit www.onestop.com to learn more and get started on your next project.

By combining advanced technology with expert support, HDI PCBs and OneStopPCB are empowering engineers to design the future of electronics. Whether you’re looking to create a compact smartphone, a high-performance medical device, or a cutting-edge aerospace system, HDI PCBs and OneStopPCB are here to help you achieve your vision.

Don’t let the challenges of miniaturization hold you back. With HDI PCBs and OneStopPCB, you can design the next generation of electronics that are smaller, faster, and more powerful than ever before. Visit www.onestop.com today to learn more and take the first step toward your next breakthrough innovation.

OneStopPCB is your partner in innovation, offering high-quality HDI PCBs that enable compact, high-performance designs. With our commitment to speed, quality, and customer satisfaction, we’re here to help you bring your ideas to life. Contact us today to learn more about how we can support your next project.

In today’s fast-paced business environment, speed is a critical factor in staying competitive. For companies that rely on PCB manufacturing, the ability to deliver high-quality PCBs quickly can make all the difference. This is where OneStopPCB excels.

OneStopPCB is committed to delivering PCBs faster than the competition, without compromising on quality. Our state-of-the-art manufacturing facilities and streamlined processes allow us to produce high-quality PCBs in record time. Whether you’re working on a tight deadline or need to quickly prototype a new design, OneStopPCB can help you meet your goals.

Another key factor that sets OneStopPCB apart from the competition is our wide variety of PCB options. We understand that every project is unique, and that’s why we offer a diverse range of PCB types, materials, and finishes to meet the specific needs of our customers.

From standard FR-4 PCBs to advanced HDI PCBs, we have the expertise and capabilities to handle even the most complex designs. Our team of experienced engineers works closely with customers to ensure that their PCBs meet all performance and reliability requirements.

At OneStopPCB, we’re proud to have helped numerous customers achieve their goals and bring their ideas to life. Here are just a few examples of the success stories we’ve been a part of:

A leading smartphone manufacturer approached OneStopPCB with the challenge of designing a compact, high-performance PCB for their latest device. By leveraging our expertise in HDI PCB technology, we were able to deliver a PCB that met all of their requirements, including a compact design, high performance, and reliable operation.

The result was a smartphone that was thinner, lighter, and more powerful than ever before. Our customer was thrilled with the results, and we’re proud to have played a key role in their success.

A medical device company needed a high-performance PCB for their latest diagnostic equipment. The device required a compact design and reliable operation, even in demanding environments.

OneStopPCB worked closely with the company to design and manufacture an HDI PCB that met all of their requirements. The result was a medical device that performed reliably, even under heavy workloads. Our customer was impressed with the quality and performance of the PCB, and we’re proud to have helped them bring their product to market.

When it comes to PCB manufacturing, OneStopPCB is the clear choice for companies that demand quality, speed, and variety. Our commitment to excellence, combined with our expertise in HDI PCB technology, makes us the ideal partner for your next project.

Whether you’re designing a compact smartphone, a high-performance medical device, or a cutting-edge aerospace system, OneStopPCB has the expertise and capabilities to help you achieve your goals. Contact us today to learn more about how we can support your next project.

OneStopPCB – Your Partner in Innovation

Simplify your PCB sourcing—get in touch now for high-quality products and efficient service!

Laser drilling for microvias

Plating and deposition to ensure electrical connectivity

Lamination of multiple layers to create complex structures

Solder mask application for protection and identification

Cutting-edge tools like laser drills enable the precision required for HDI designs. Innovations in plating techniques enhance conductivity and durability.

Ensure reliability through stringent testing like electrical continuity and thermal cycling. Automated optical inspection (AOI) is also used to detect defects early.

| Specifications | PCB Capabilities |

| PCB Layers | 4 ~34 layers |

| High-Density Layers | Up to 18 layers |

| Delivery Time | 1 day to 3 weeks |

| Stackup | 1+N+1, 2+N+2, 3+N+3, 4+N+4 |

| PCB Via | Blind via, Buried via, Staggered via, Stacked via, Skip via |

| Minimum Laser Drill Diameter | 0.075mm |

| Final PCB Thickness | 0.15mm |

| Minimum Trace Width/Space | Flex/rigid-flex PCBs: 1.6mil/1.6mil Rigid PCBs: 3mil/3mil |

| Production Capability | 3000m² per day |

| Copper Thickness | 100μm to 125μm |

| Impedance Control | 90Ω ~100Ω |

| Technical Feature | 90Ω & 100Ω Differential impedance, thick cooper |

| Silkscreen | White, Black, Red,etc. |

| Soldermask | Green, Blue, Purple, White, Black, Pink,Orange |

| Surface finish | OSP, HASL, Lead Free HASL,ENIG,Immersion Tin,Immersion silver, Hard gold plating,etc. |

Choosing onestoppcb for your HDI PCB needs comes with numerous advantages that set us apart in the competitive electronics manufacturing industry:

Speed and Efficiency: Our streamlined manufacturing processes ensure rapid prototyping and on-time delivery, helping you maintain tight project schedules without compromise.

High Precision and Quality: Equipped with state-of-the-art facilities, we specialize in crafting high-density interconnect (HDI) PCBs with unparalleled accuracy and reliability, perfect for sophisticated and compact electronic designs.

Diverse Customization Options: Whether you need multi-layer, blind and buried vias, or microvia solutions, we offer a wide range of configurations to meet your specific requirements.

Global Trust and Expertise: With extensive experience exporting to the U.S., Europe, Vietnam, and South America, we understand and adhere to international standards, ensuring consistent quality every time.

Personalized Support: Our dedicated team of engineers and account managers work closely with you, providing expert guidance and responsive service to simplify your supply chain.

Choosing onestoppcb means partnering with a factory that values speed, diversity, and exceptional quality, ensuring your success in every project.

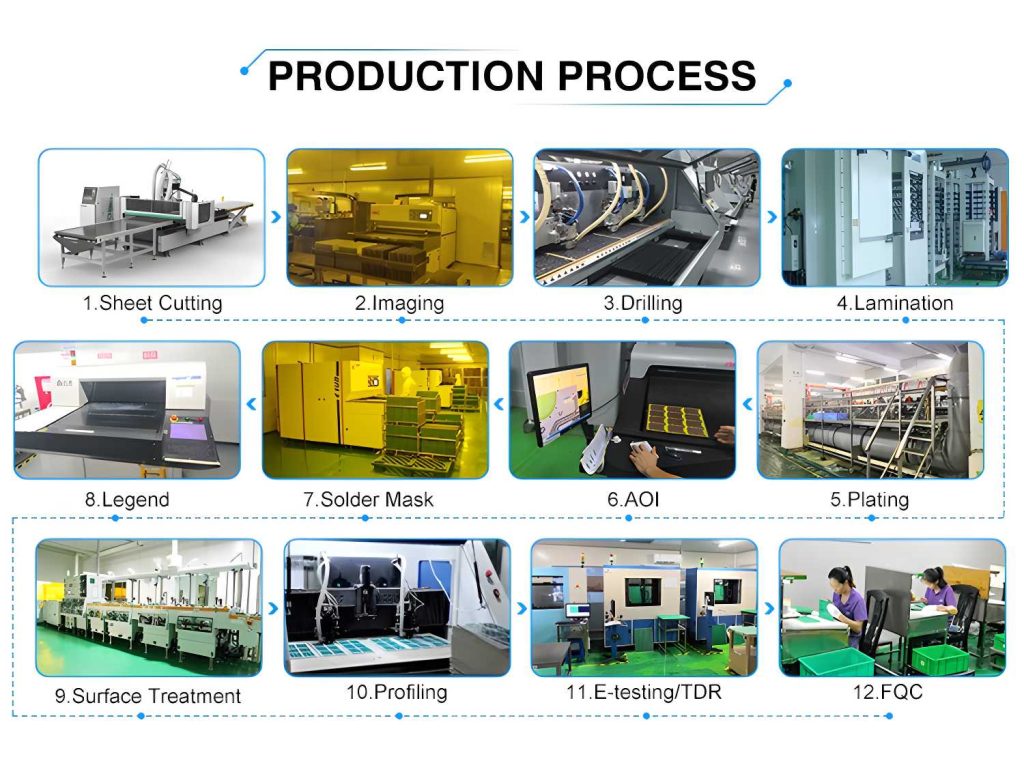

here are more pictures of our factory’s equipment display in our company profile, please click here.

● IATF 16949:2016

● ISO 9001:2015

● ISO14001:2015

● ISO13485:2016

● UL

Furthermore, all our products adhere to the IPC & ROHS Standards. It is our continuous endeavor to produce premium quality PCB products.

We understand you may have questions about our products and services. Here, we provide answers to common queries regarding our HDI PCB.

High-density interconnect, or HDI, circuit boards are printed circuit boards with a higher wiring density per unit area than traditional printed circuit boards.

HDI PCBs differ significantly from standard boards by incorporating multiple layers, micro-vias under 0.008 inches in diameter, and specialized via-in-pad processes. They often include blind, buried, and stacked vias, allowing exceptionally dense circuitry where traces and spaces both measure below 0.005 inches. This combination results in superior miniaturization and performance, making HDI PCBs ideal for mission-critical applications.

Your Trusted HDI PCB Manufacturer Since 2011

onestoppcb brings the advanced capabilities and decades of expertise required to handle all your fabrication and manufacturing needs, including high-density interconnect (HDI) PCBs. With HDI boards gaining increasing popularity across diverse sectors—such as medical, military, and aerospace—we stand ready to deliver the reliability and performance demanded by these critical industries.

PCBs built with high-density interconnect (HDI) technology generally occupy a smaller footprint, as they fit more components into a tighter space. By incorporating blind, buried, and micro vias, along with via-in-pad placements and very fine trace widths, HDI designs efficiently pack a higher component density onto a smaller board.

HDI PCBs deliver substantial advantages. They enable a more compact device footprint and can enhance overall electrical performance, supporting higher data transmission speeds. Moreover, they accommodate more input/output connections within a smaller area.

At onestoppcb, our 4-layer HDI manufacturing process closely resembles standard PCB production, with the primary distinction being the order in which holes are drilled. We start by mechanically drilling buried vias between layers 2 and 3, then move on to the through-holes from layers 1 to 4. Finally, we form blind vias between layers 1-2 and 4-3. This carefully sequenced approach ensures optimal board integrity and reliable signal performance.

At onestoppcb, we use a combination of polymer resin (dielectric)—with or without fillers—reinforcement materials, and metal foil as the primary building blocks of our circuit boards. In a typical layer construction, alternating layers of dielectric and metal foil are stacked to achieve the desired thickness and electrical performance. This process ensures both reliable functionality and structural integrity for a wide range of applications.

We’ve found that PCB dimensions and shape play a crucial role in determining cost. Larger boards require additional materials and take longer to produce, driving up expenses. Meanwhile, PCBs with unusual shapes may need specialized tooling or more complex processes, which can also contribute to higher costs

Simplify your PCB sourcing—get in touch now for high-quality products and efficient service!

ONESTOPPCB

1-4/F Property Office Building, ZhengFeng North Road, Shenzhen, China 518103

Phone: +86-0755-36309132

1-4/F Property Office Building, ZhengFeng North Road, Shenzhen, China 518103

Get in Touch with Onestoppcb – Your Premier PCB Partner

1.Fast Turnaround Time: Our streamlined manufacturing process ensures rapid prototyping and production, meeting tight deadlines effortlessly.

2Diverse Product Range: We offer an extensive variety of PCB types and designs, catering to the unique needs of engineers and procurement teams.

3Quality Assurance: With rigorous quality checks and high standards, we consistently deliver reliable and durable PCBs, minimizing risks for your projects.

Simplify your PCB sourcing—get in touch now for high-quality products and efficient service!